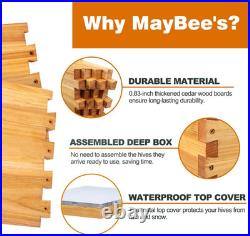

Complete Beekeeping Starter Kit? – This 10-frame Langstroth hive kit includes 1 deep brood box, 1 medium super box, 20 frames with beeswax-coated plastic foundations, and essential accessories like a waterproof metal top cover, queen excluder, and entrance reducer. Perfect for beginners and experts, it provides everything needed to start or expand your beekeeping journey. Transparent Bee Window? – Our transparent observation window features integrated ventilation to safely monitor bee activity and hive conditions without intrusion. The design maintains natural airflow to regulate humidity and prevent harmful buildup while allowing visual tracking of honey production, colony health, and brood development. Ideal for stress-free inspections that preserve hive rhythms and enhance honey quality. Heavy-Duty Beeswax Coating? – Both hive boxes and foundations are fully dipped in 100% natural beeswax, creating a waterproof, durable barrier that eliminates the need for toxic paint. The thick wax coating protects against weather, reduces maintenance, and ensures a safe, long-lasting environment for your bees. Premium Cedarwood & Dovetail Design? – Crafted from high-quality cedarwood, the hive resists warping, cracking, and shrinking. Precision pre-cut dovetail joints and pre-drilled holes enable quick, tool-free assembly, while the tight-fitting design ensures structural integrity for years of use. Bee-Friendly Ventilation & Space? – The ventilated inner boards and detachable bottom board promote airflow and easy cleaning. With dimensions optimized for Langstroth standards (deep box: 9-5/8? Height; medium box: 6-5/8? Height), the hive offers ample space for colony growth and efficient honey production. Durable, Safe, and Time-Saving? – Features food-grade plastic foundations for healthy honey storage, pre-assembled waterproof covers, and a 30-minute setup time. The cedarwood’s natural insulation keeps bees comfortable in all seasons, while the ergonomic design prioritizes both bee health and beekeeper convenience.