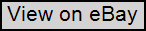

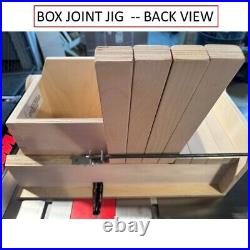

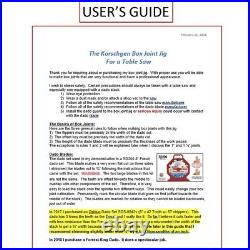

As an active beekeeper, I invented this table saw jig in 2013 to make ¾ box joints for construction of standard Langstroth bee hive boxes of 10-frame, 8-frame, or nuc configuration. Few jigs provide the simplicity of operation, efficiency, and safety as this jig. See my YouTube videos (“Korschgen bee hive box jigs”) and my complimentary hive handle jig. From high quality Baltic birch plywood. The jig components are sled, sliding box, flippers, blade guard/ dust box, aluminum T-Track calibration runners, and ¾ offset keys – for 2, 4, and 8 boards. The jig can be configured to any table saw with an arbor that accepts a ¾ dado stack. 2+ hp motor with 8dado stack is best. A detailed user’s guide is provided that also includes plans for making a frame rest jig. There are several advantages of my jig over others that are commercially manufactured for making generic box joints. They are as follows. Once calibrated to the table saw, the only step to begin production is to adjust the height of the dado blade. It provides a fast and simple method for indexing the placement of the hive boards in the path of the dado saw blades using a series of flippers on a sled and sliding box assembly. The jig permits the clamping and milling of up to 8 boards at a time with powerful saw and sharp dado blade. It can be used to cut joints in the paired sides (19 7/8″ and 16 ¼” / 14″) of a hive box independently or matching pairs of boards (19 7/8″ or 16 ¼” / 14″) by offsetting the 19 7/8 boards. It includes a safety guard that provides protection of the operator and removes sawdust when connected to your shop vacuum. Box joints are a preferred joint because of the strength of the long-grain to long-grain contact between the notches, which provides a solid gluing and fastening surface. I have designed an accessory sets of flippers to make 1″ or 1 ½” box joints using a ½” or ¾” dado blade respectively. What do you need besides this jig? Stationary table saw with 2-5 horsepower. 8 dado stack to fit your saw arbor. At least two IRWIN QUICK-GRIP Bar Clamps Heavy-Duty 600#, 12 (1964712) or similar clamps. You may want to make a simple shim box to take up extra space inside the sliding box. Set of plastic tapered putting knives to shim. This jig overcomes many of the disadvantages of an accessory for stationary woodworking machines. It takes advantage of the machine’s work table, embedded miter gage slots, and cutting blades or bits. It is used to make box joints (also called finger joints) using a sled and sliding box design on a table saw or router/shaper table. The sled is an open box made with two rails, a bottom piece, one end piece, and two miter gage slot runners fastened to the underside of the jig’s bottom. The sled is calibrated to the machinery table and is designed to move forward and backward along the machine table using the miter slots as guides. A sliding box, with potentially multiple configurations, is precisely mounted inside the sled using tongue and groove attachments such that the sliding box is suspended above the bottom of the sled. The sliding box moves from side to side inside the sled. Multiple workpieces are clamped into the sliding box and box joints are cut as the sled is pushed through the cutting tool which may be a saw blade, dado blade, or router/shaper bit. A sliding box that is suspended inside the sled moves from side to side as the flippers accurately space the workpieces to the next cutting position. Compared to most other commercially available jigs, this invention is simple to construct because of the relatively small number of parts, is easy to use, and it provides efficient and accurate results.